What are the different types of brush discs available for floor scrubbers

Nylon Brush Discs: Nylon brush discs are ideal for cleaning delicate surfaces such as ceramic and polished concrete floors. The bristles are soft and flexible, making them gentle on the surface while still providing effective cleaning.

Polypropylene Brush Discs: Polypropylene brush discs are durable and resistant to chemicals, making them ideal for cleaning rough and uneven surfaces such as concrete and grout. The bristles are stiff and abrasive, making them effective in removing tough stains and dirt from the surface. These brush discs are also long-lasting and can withstand heavy use without showing signs of wear and tear.

Grit Brush Discs: Grit brush discs are ideal for cleaning heavily soiled floors that require deep scrubbing. The brush disc is coated with abrasive particles such as silicon carbide or diamond, which provide a more aggressive scrubbing action. These brush discs are ideal for removing grease, grime, and stubborn stains from floors.

Wire Brush Discs: Wire brush discs are ideal for cleaning concrete surfaces that have deep grooves or are heavily soiled. The bristles are made of steel wire, which provides a more aggressive scrubbing action, making them effective in removing rust, paint, and other stubborn stains.

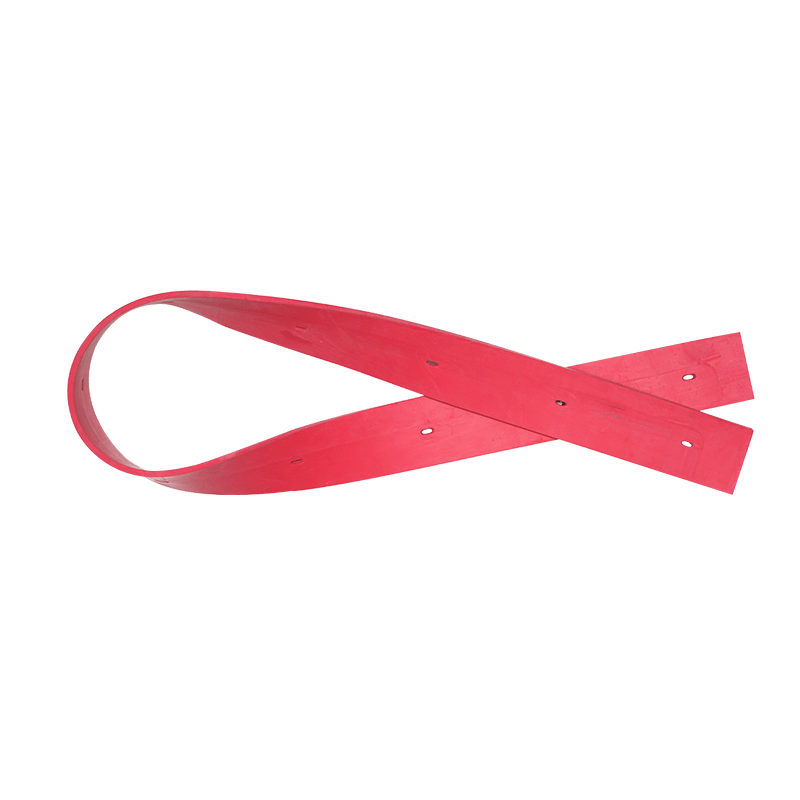

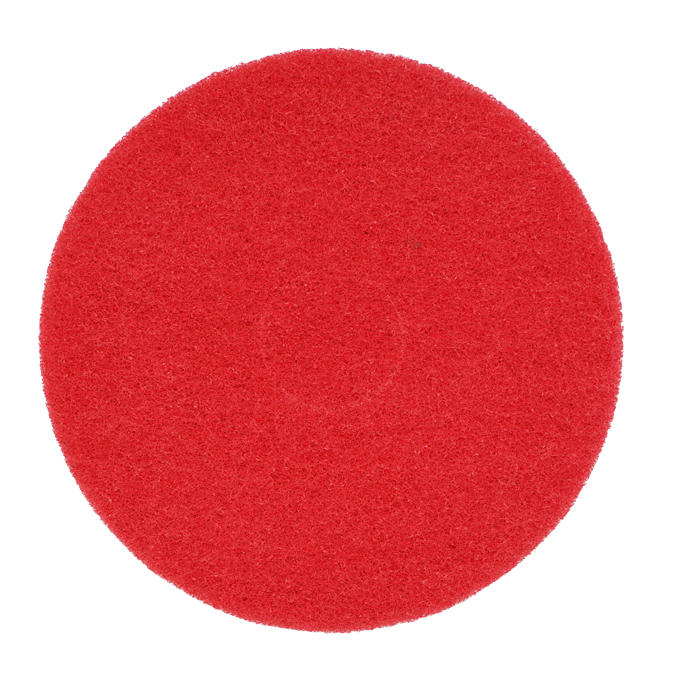

Scrubbing Pads: Scrubbing pads are an alternative to brush discs, which can be used to clean delicate surfaces such as marble and terrazzo. These pads are made of non-abrasive materials such as polyester, nylon, and natural fibers and are available in various grit levels. Scrubbing pads are also ideal for use on floors that have a high gloss finish, as they do not leave scratches or marks on the surface.

How do brush discs contribute to the overall performance of a flocculent scrubber in the mining industry

Enhanced mixing: Brush discs are designed to create turbulence in the wastewater, which promotes the mixing of chemicals used for flocculation. This enhances the contact between the chemicals and the suspended solids, allowing them to form larger flocs that can be more easily separated from the wastewater.

Increased surface area: The bristles on the brush discs provide a large surface area for floc formation. This increases the chances of suspended solids coming into contact with the chemicals used for flocculation, leading to more effective treatment of the wastewater.

Durability: Mining wastewater can be highly abrasive, which can cause damage to equipment components. Brush discs, however, are made from durable materials that can withstand the harsh conditions of mining wastewater treatment.

Easy maintenance: Brush discs are easy to clean and replace, which minimizes downtime for the scrubber. This is important in the mining industry, where continuous operation is critical to the success of mining operations.

Customizable: Brush discs can be customized to suit the specific needs of mining operations. This includes variations in the size and shape of the brushes, as well as modifications to the disc's rotational speed and direction, to optimize the performance of the scrubber.

Cost-effective: Brush discs are a cost-effective solution for flocculent scrubbers in the mining industry. They are relatively inexpensive to manufacture and are easy to install and maintain, which reduces operating costs.

英语

英语 中文简体

中文简体